Modern warehouses are no longer just storage spaces filled with shelves and pallets. They are…

7 Must-Have Metrics on Your Warehouse KPI Dashboard

Reading Time: 3 minutes

In the world of logistics and supply chain management, efficiency is everything. Warehouses are no longer just storage spaces—they are high-performance hubs that directly impact customer satisfaction, profitability, and operational success. To optimize your warehouse operations, a Warehouse KPI Dashboard becomes an essential tool.

But what exactly should you track? And why are KPIs so critical for warehouse performance?

Let’s dive deep into the essentials.

What Are Warehouse KPIs?

Warehouse KPIs (Key Performance Indicators) are measurable metrics that help you evaluate the performance of your storage, fulfillment, and logistics operations. These KPIs form the backbone of every Warehouse Management Dashboard, offering insights that are vital for decision-making and process improvement.

From stock accuracy to order picking speed, every data point you track via your Warehouse KPI Dashboard gives you a clearer picture of how your warehouse is functioning in real time.

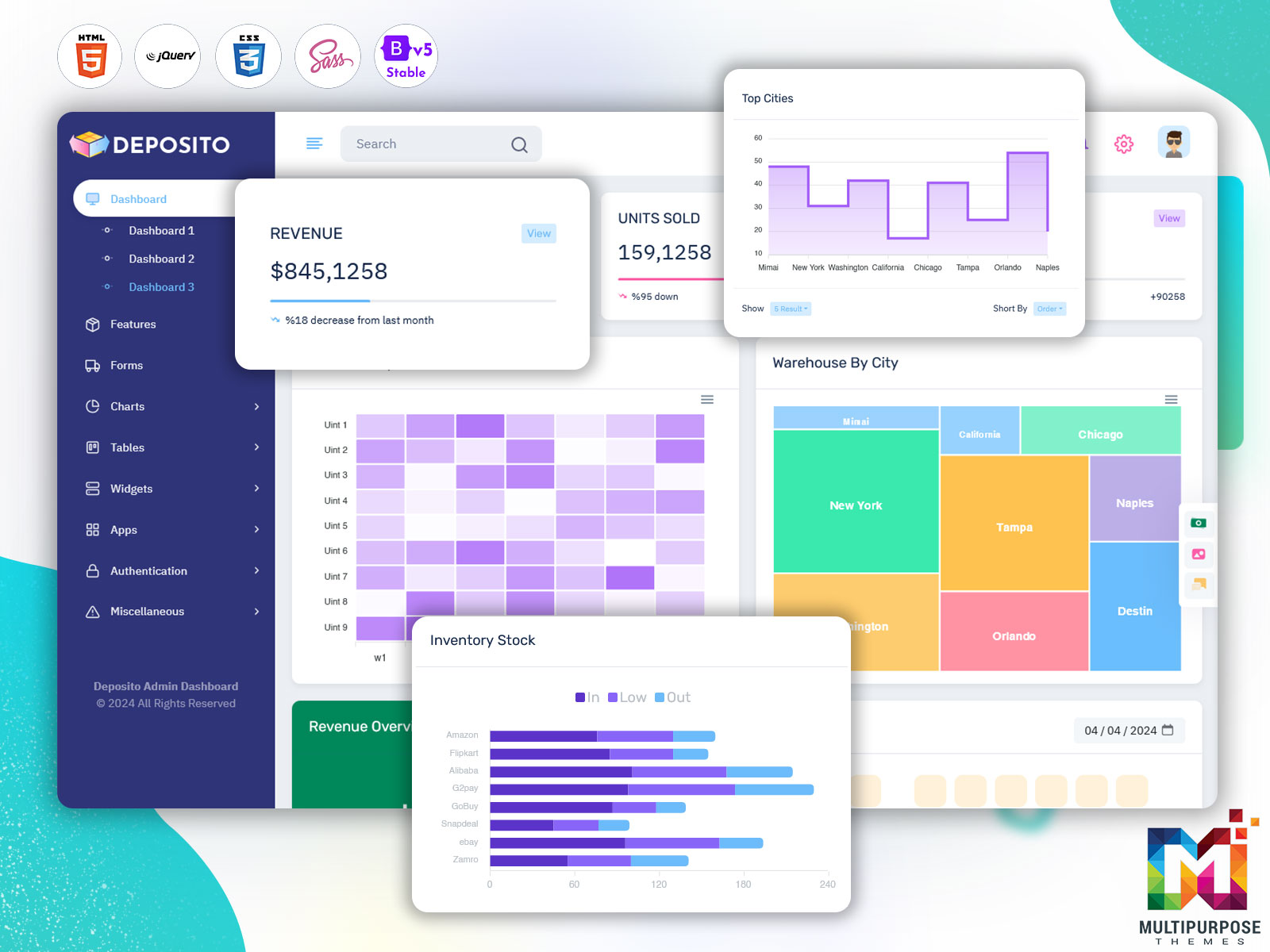

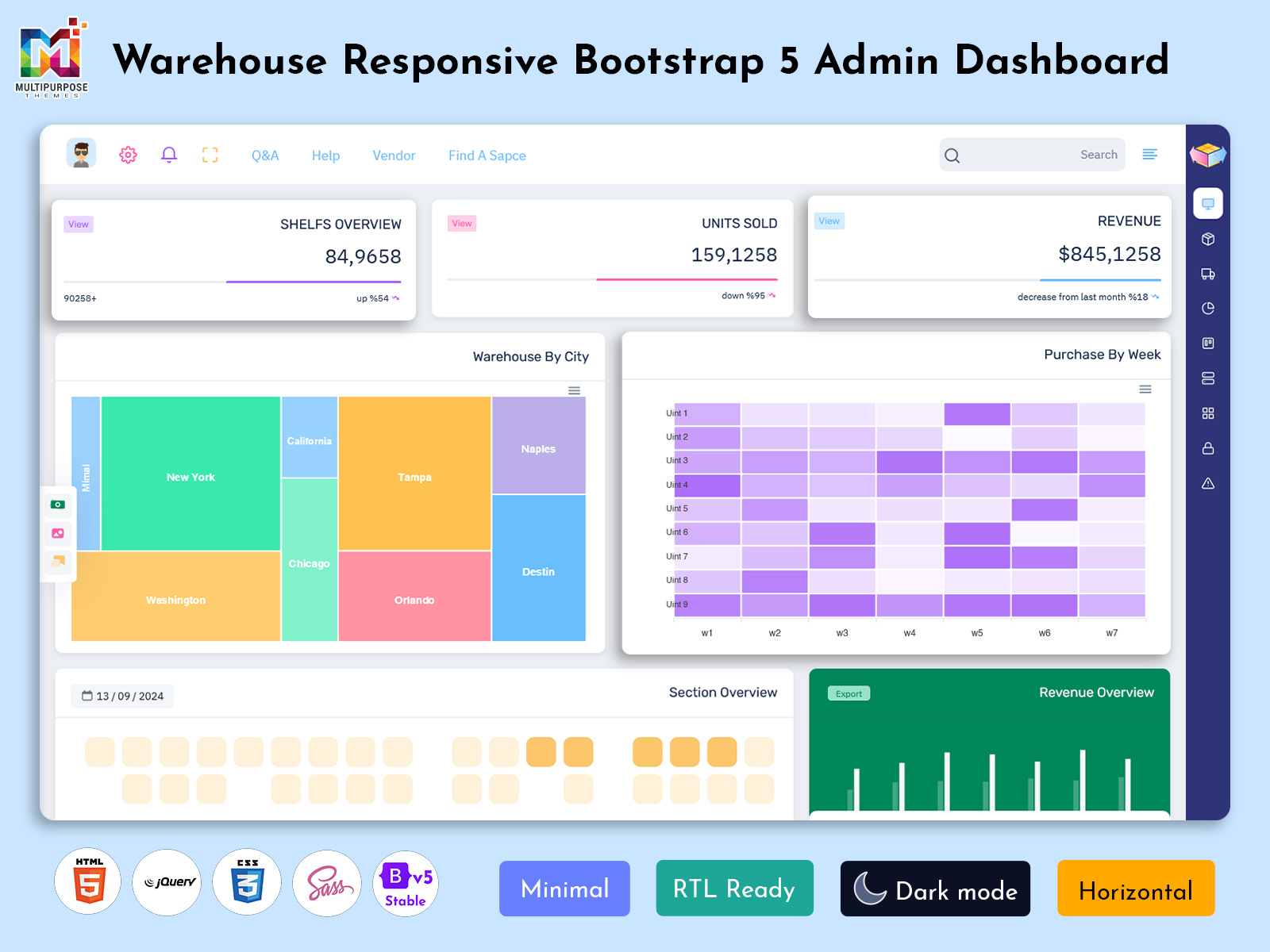

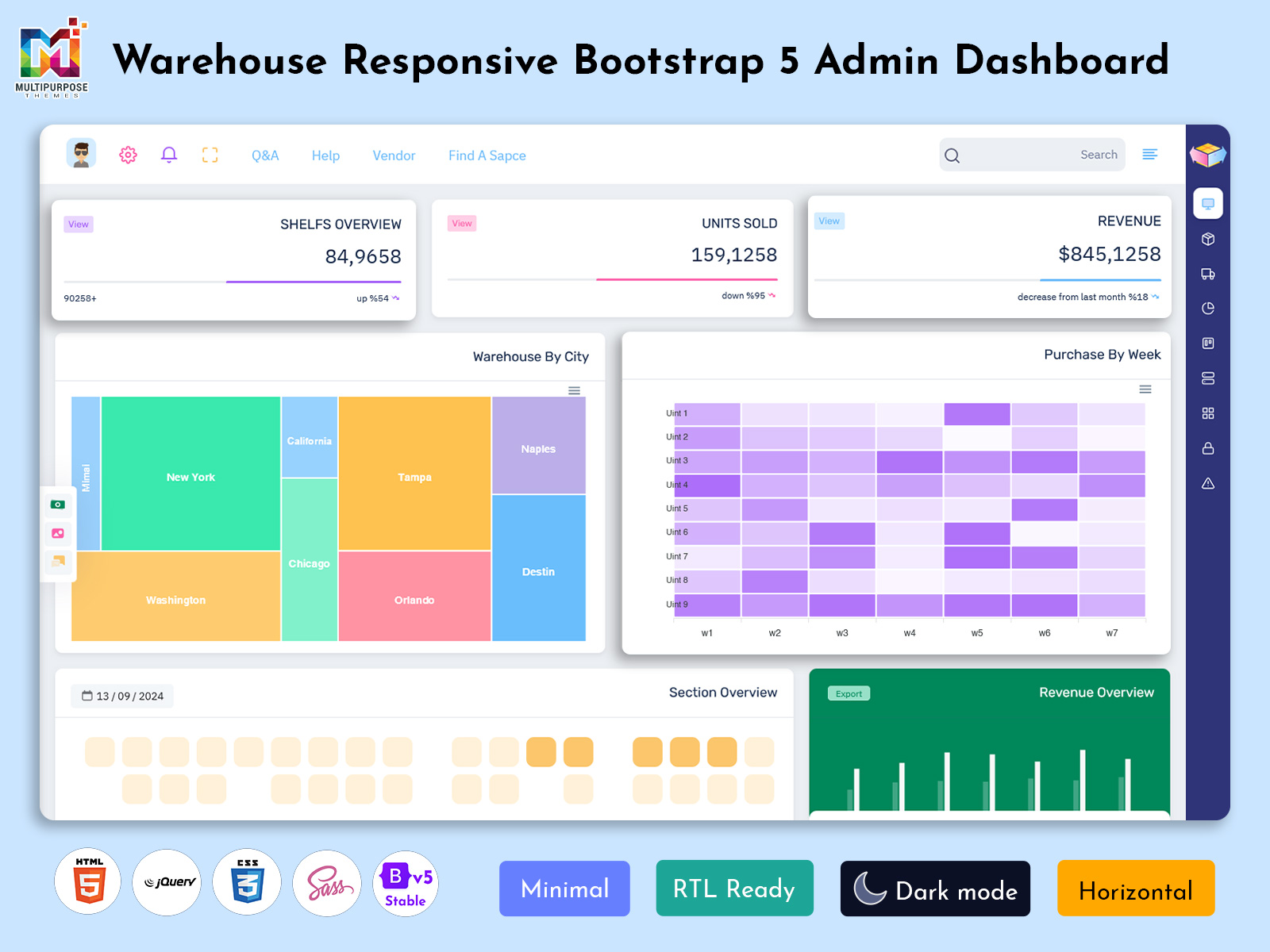

Explore Warehouse or Logistic KPI Dashboard Layouts

Click Button – Experience Dashboard Design

Dashboard – 1: Light

BUY NOW DEMO

Dashboard – 2: Light

BUY NOW DEMO

Dashboard – 3: Light

BUY NOW DEMO

Dashboard – 1: Dark

BUY NOW DEMO

Dashboard – 2: Dark

BUY NOW DEMO

Dashboard – 3: Dark

BUY NOW DEMO

Warehouse KPIs: Benefits

Implementing a powerful Warehouse KPI Dashboard offers a range of advantages:

– Real-time monitoring of warehouse operations

– Improved inventory control and demand forecasting

– Better visibility across supply chains

– Enhanced resource utilization and labor management

– Streamlined operations through actionable insights

Whether you’re using a Storage Dashboard, Procurement Dashboard, or an Inventory Dashboard, tracking the right KPIs is the key to achieving operational excellence.

The Importance of Warehouse KPIs

Ignoring warehouse KPIs is like flying blind in logistics. When you integrate KPIs into a robust Warehouse Metrics Dashboard, you gain:

– Data-driven insights to reduce operational costs

– Ability to meet customer expectations with timely deliveries

– Improved staff productivity through measurable performance indicators

– Optimization of inventory levels, reducing overstock or stockouts

By aligning your daily operations with what your Inventory Management Dashboard or Warehouse KPI Dashboard reveals, you can consistently improve output and service quality.

Dashboard Demo Video

Key Metrics to Track in Your Warehouse KPI Dashboard

When setting up or optimizing your Warehouse KPI Dashboard, make sure to include these crucial metrics:

1. Section Overview

This offers a top-level summary of key areas like inventory value, space usage, and real-time alerts—ideal for any Warehouse Manager Dashboard.

2. Top Cities

Track where your demand is strongest, making it easier to plan supply chain strategies with the help of your Transport Management System Dashboard.

3. Inventory Stock

Stay informed about available stock levels. A vital metric in your Inventory Dashboard to prevent overstocking or shortages.

4. Revenue Overview

Monitor earnings against sales, returns, and shipping expenses. Integrate this into your Procurement Management Dashboard for financial planning.

5. Units Sold

Understand product movement trends to adjust restocking decisions on your Storage Management Dashboard.

6. Purchase By Week

Analyze procurement behavior and plan accordingly with a real-time Procurement Dashboard.

7. Warehouse By City

Track performance per location through your Warehouse Dashboard, especially useful for multi-site operations.

Tips for Improving Receiving Efficiency in Warehouses

Receiving efficiency plays a huge role in warehouse performance. Here are a few practical tips:

– Standardize receiving processes with barcoding and scanning tools

– Use your KPI Dashboard to identify delays in receiving

– Assign dedicated receiving zones and staff roles

– Measure receiving time and supplier performance via your Warehouse Management Dashboard

Integrating real-time metrics into your Warehouse KPI Dashboard ensures that bottlenecks are addressed promptly, saving both time and money.

Frequently Asked Questions

Q1: How to measure warehouse efficiency?

You can measure efficiency using a Warehouse Metrics Dashboard that tracks order cycle time, picking accuracy, receiving speed, and inventory turnover rate.

Q2: What is the KPI for inventory?

Common inventory KPIs include inventory accuracy, turnover rate, days of inventory on hand, and backorder rate—all easily monitored via an Inventory Management Dashboard.

Q3: How do warehouse workers measure performance?

Warehouse staff performance is tracked through metrics like picks per hour, order accuracy, and on-time shipment rate, which can be viewed in a Warehouse Manager Dashboard.

Q4: How do KPIs enhance customer satisfaction?

KPIs ensure that operations run smoothly, reducing errors and delays. A well-maintained Warehouse KPI Dashboard leads to timely deliveries and better service quality.

Q5: What is the importance of inventory accuracy?

Inventory accuracy is crucial for avoiding stockouts, minimizing waste, and ensuring smooth operations. It’s one of the key metrics in any reliable Storage Dashboard or Inventory Dashboard.

Final Thoughts

In today’s data-driven logistics environment, having the right Warehouse KPI Dashboard is not just a luxury—it’s a necessity. Whether you’re tracking inventory, procurement, or transport metrics, your Warehouse Dashboard acts as your command center.

When powered by integrated tools like the Procurement Management Dashboard, Transport Management System Dashboard, and Storage Management Dashboard, you gain full control over your supply chain.

The result? Greater efficiency, fewer errors, higher profits—and most importantly, happy customers.

skip to Main Content

skip to Main Content

This Post Has 0 Comments