At the top of this blog, you can watch a complete Warehouse Metrics Dashboard demo…

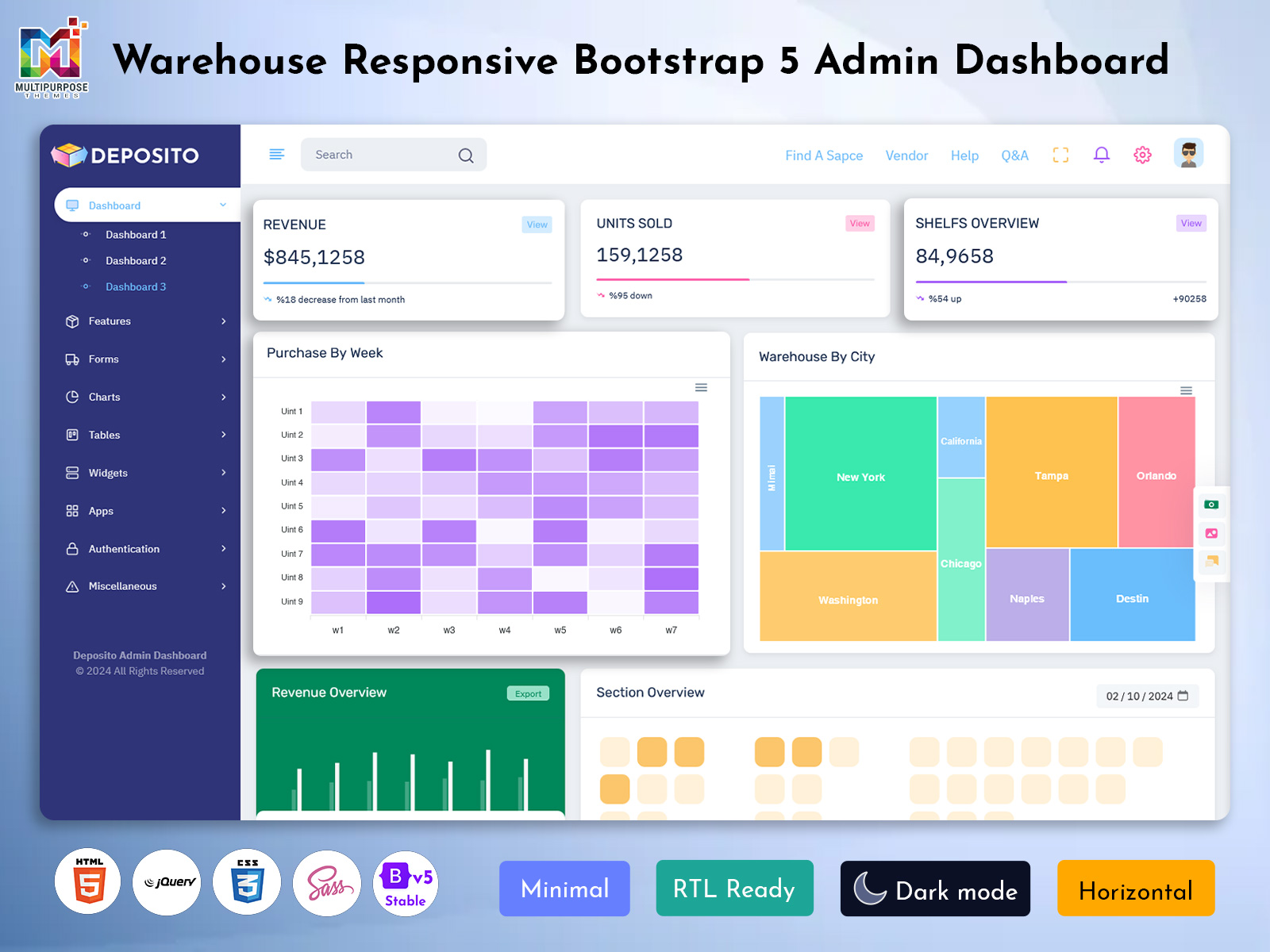

Warehouse Manager Dashboard – High Level Stock Tracking Ability

Reading Time: 7 minutes

A Warehouse Manager Dashboard is a critical tool used by businesses to manage and optimize their warehouse operations. It provides a real-time, comprehensive overview of key metrics and performance indicators within a warehouse. By leveraging data visualizations, graphs, and interactive tools, this dashboard helps warehouse managers and staff make data-driven decisions that can improve efficiency, reduce operational costs, and enhance customer satisfaction.

This article explores the features, importance, and benefits of a Warehouse Management Dashboard, and how it contributes to the overall success of a warehouse operation.

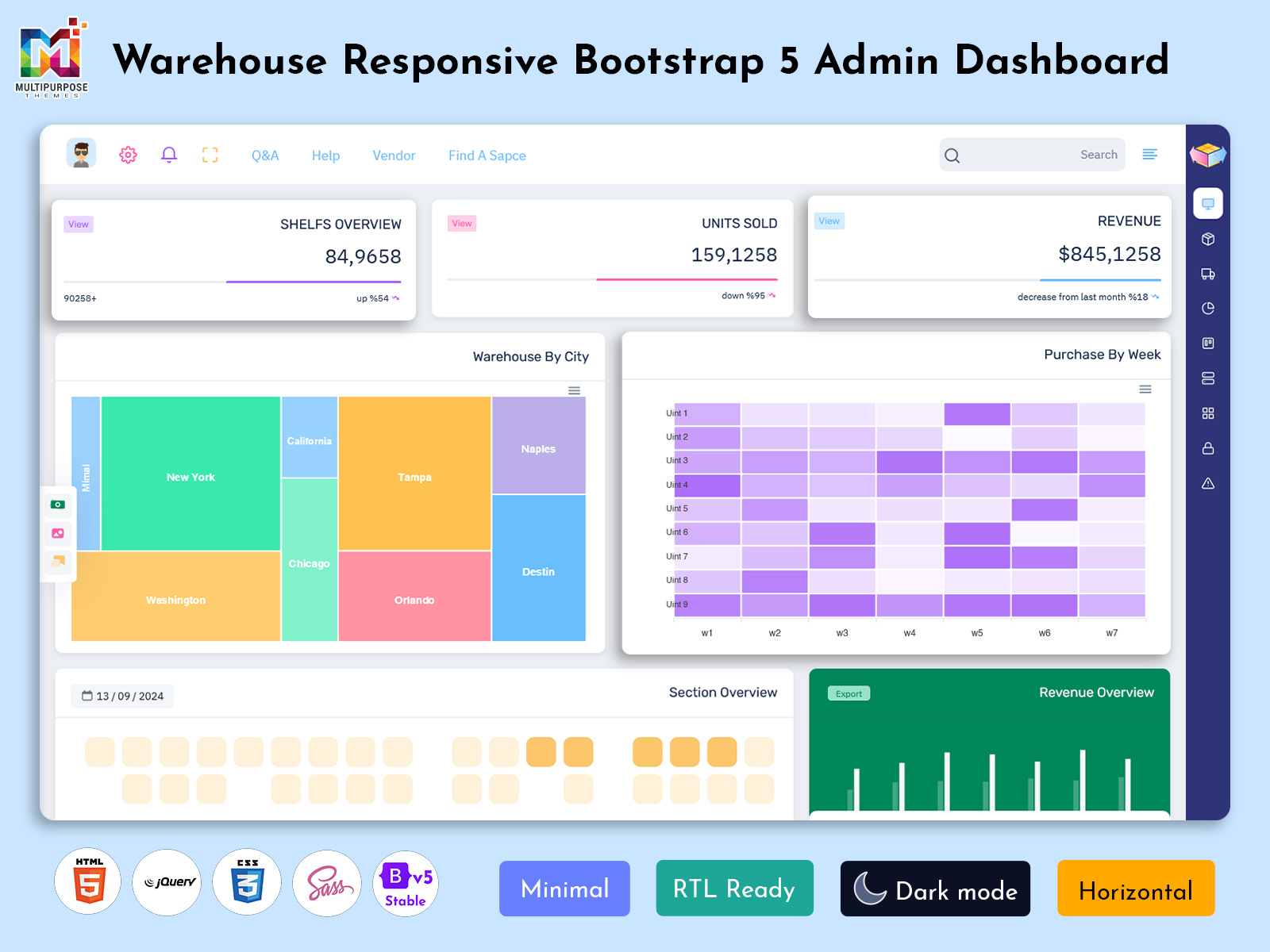

Dashboards of Warehouse Admin

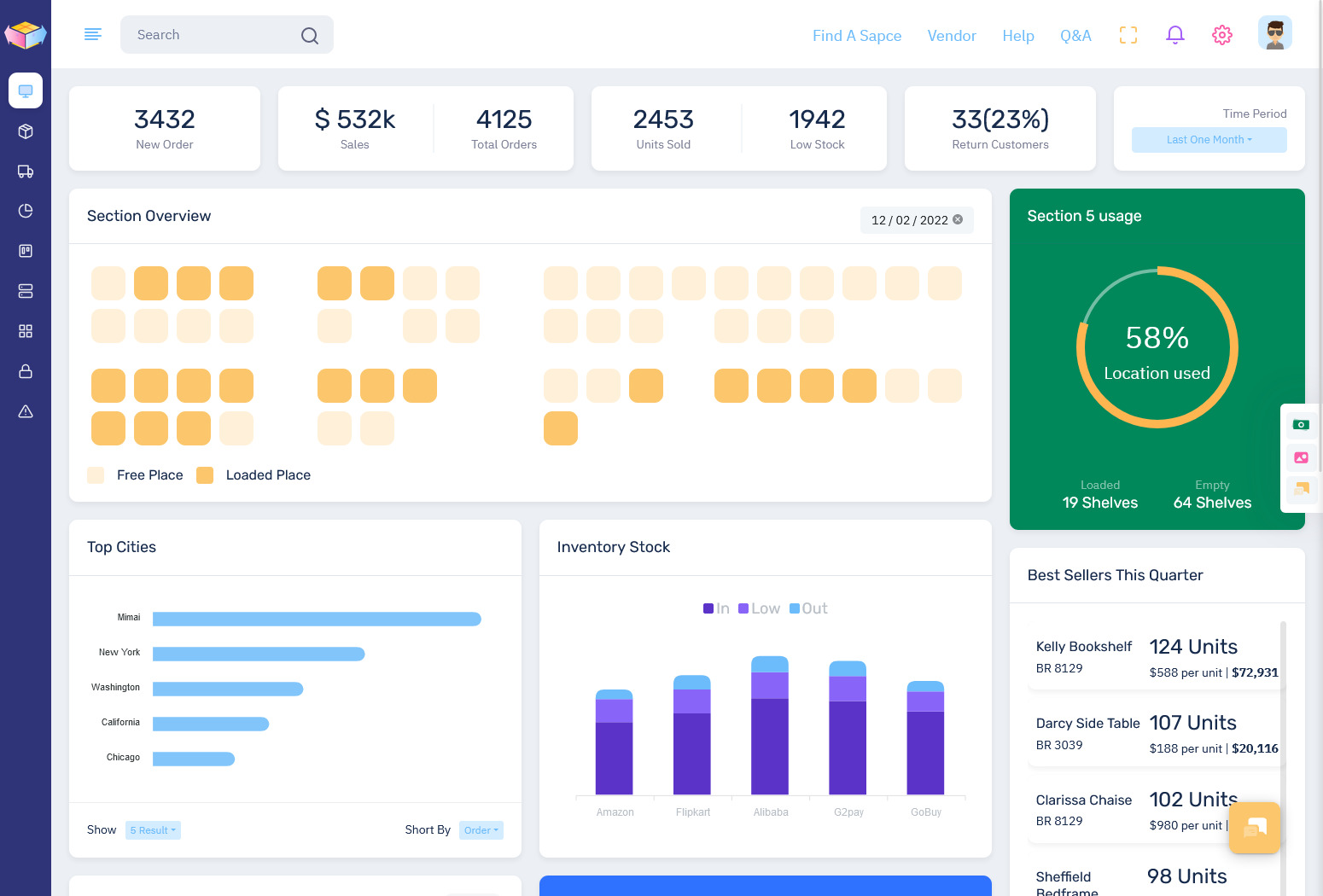

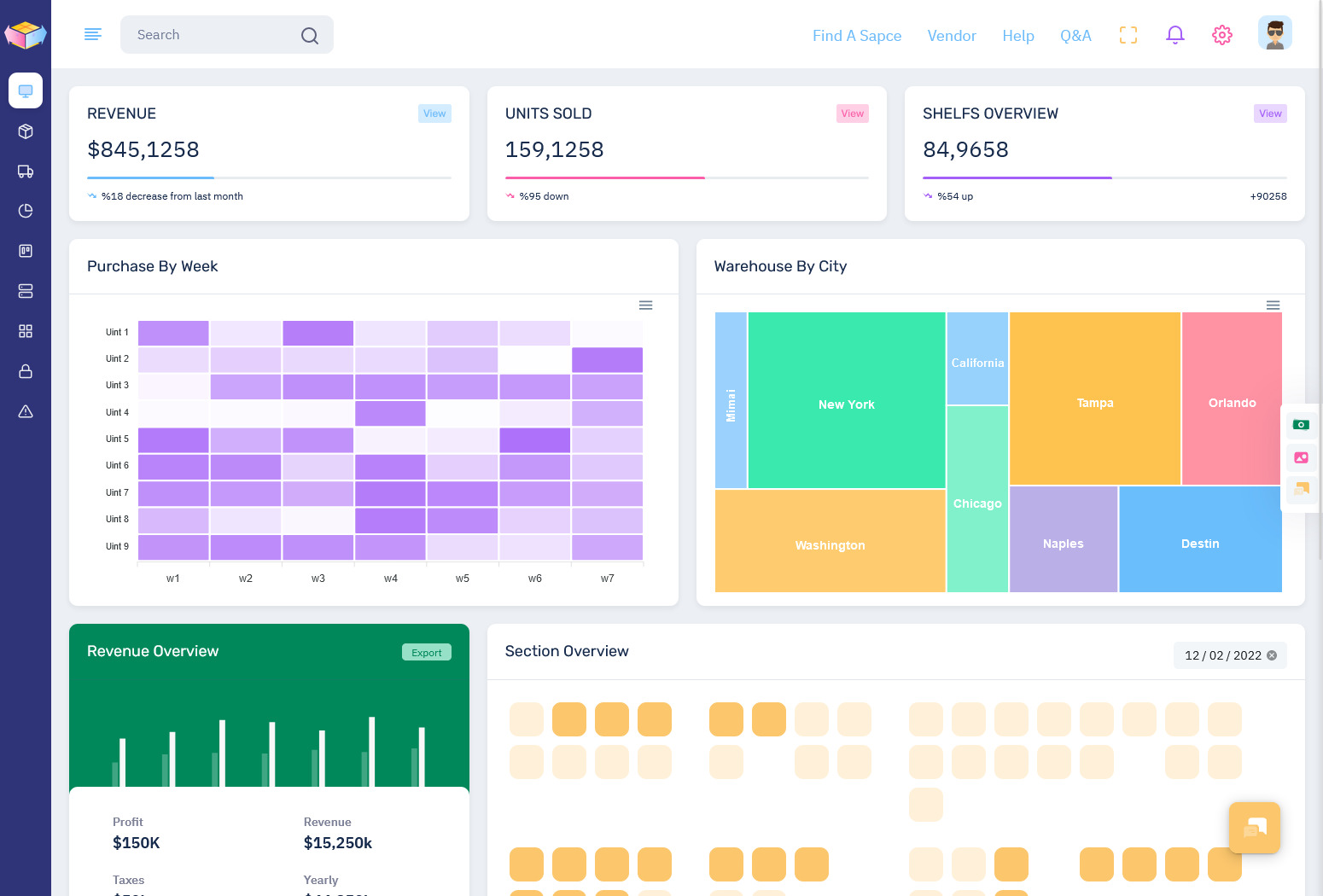

LTR Style Mini Sidebar Dashboards – Light Version

MORE INFO / BUY NOW DEMO

MORE INFO / BUY NOW DEMO

MORE INFO / BUY NOW DEMO

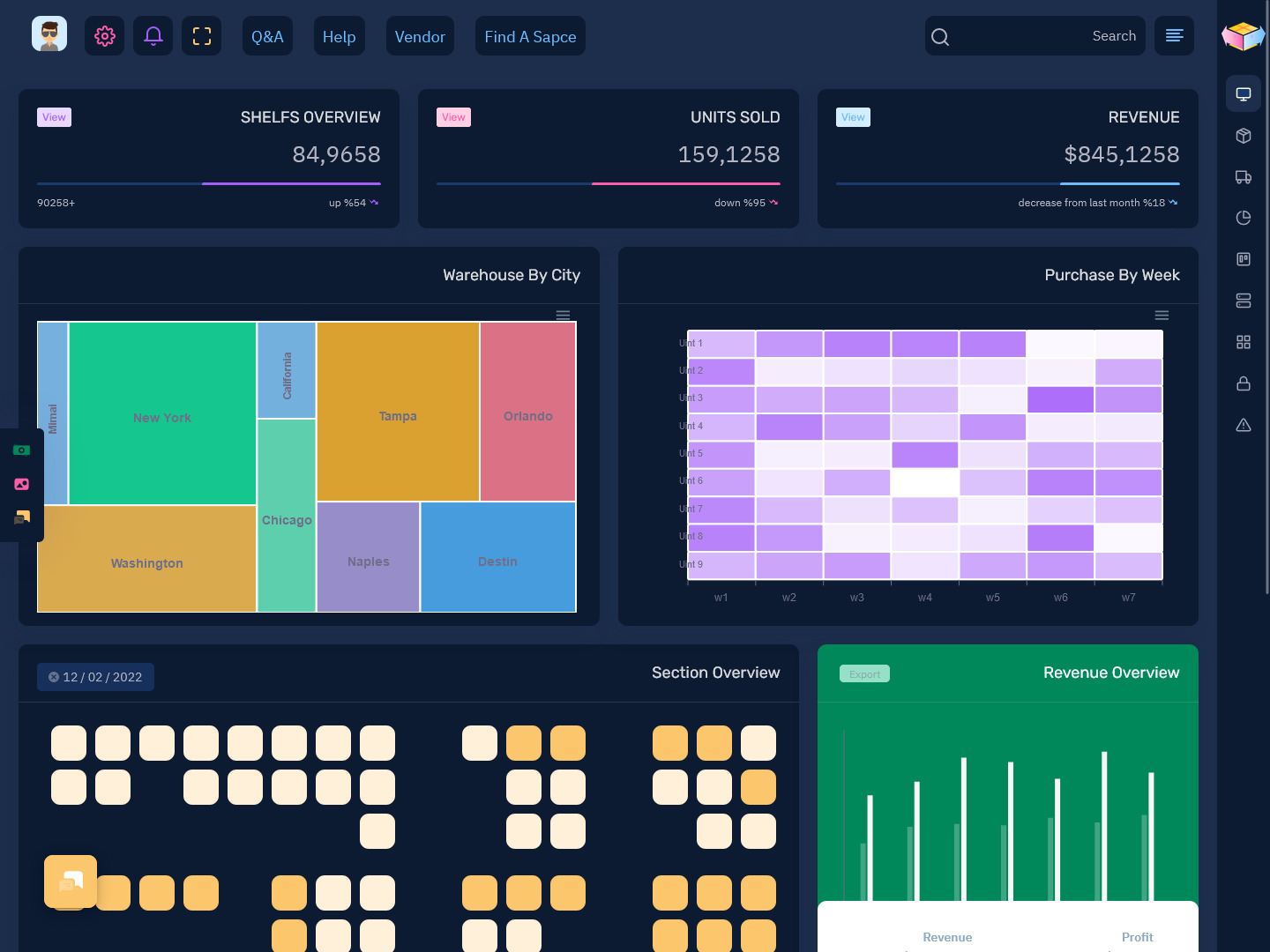

RTL Style Mini Sidebar Dashboards – Dark Version

MORE INFO / BUY NOW DEMO

MORE INFO / BUY NOW DEMO

MORE INFO / BUY NOW DEMO

1. Introduction to Warehouse Management Systems (WMS)

Warehouse management is a complex and dynamic process that involves overseeing the storage, movement, and distribution of goods within a warehouse. It requires managing inventory, tracking orders, coordinating logistics, and ensuring the timely dispatch of goods. Efficient warehouse management is essential for businesses to stay competitive, reduce costs, and meet customer expectations.

A Warehouse Management System (WMS) is a technology-driven solution designed to streamline these processes. It automates tasks, manages inventory in real time, and optimizes the flow of goods. However, for effective use, a WMS needs to be paired with a Warehouse Manager Dashboard, which provides a user-friendly interface for monitoring and analyzing warehouse activities.

2. Features of a Warehouse Management Dashboard

A Workforce Management Dashboard offers an interactive, real-time snapshot of warehouse operations. It consolidates all important data into a single, easily accessible view. The features of such dashboards are designed to help managers and staff track the progress of key metrics and identify potential issues before they escalate.

Some of the core features of a Warehouse Management Dashboard include:

a. Real-Time Data Visualization

The primary purpose of a Warehouse Dashboard is to present real-time data through dynamic charts, graphs, and tables. This data might include information on inventory levels, order statuses, shipments, and workforce productivity. Managers can monitor these metrics in real-time to make informed decisions about resource allocation and operational priorities.

b. Inventory Tracking and Monitoring

Inventory management is one of the most critical aspects of warehouse operations. A WMS Dashboard provides up-to-the-minute data on inventory levels, stock locations, and the movement of goods. With this information, warehouse staff can quickly identify stock discrepancies, avoid stockouts, and maintain an optimal inventory level.

c. Order Management

A key feature of a WMS Dashboard is the ability to track the status of orders. The dashboard provides insights into pending, in-progress, and completed orders. This helps managers ensure that orders are processed on time and shipped to customers without delays.

d. Performance Metrics

To evaluate the effectiveness of warehouse operations, the Warehouse Dashboard provides key performance indicators (KPIs) such as order fulfillment rates, average picking times, cycle times, and worker productivity. These KPIs are essential for understanding operational efficiency and identifying areas for improvement.

e. Workforce Management

Workforce management is another critical function of a Inventory Management Dashboard. The system helps track the performance of warehouse staff, monitor labor costs, and ensure that staffing levels are adequate. Managers can also assign tasks, monitor progress, and identify bottlenecks related to human resources.

f. Shipping and Receiving

A WMS Dashboard allows managers to track incoming and outgoing shipments. It provides visibility into shipping schedules, delivery statuses, and potential delays. This is essential for ensuring that the warehouse can handle inbound shipments efficiently and dispatch goods to customers in a timely manner.

g. Alerts and Notifications

Proactive alerts and notifications are important features that help prevent potential issues. For example, managers can receive real-time alerts about low inventory levels, backlogged orders, or delayed shipments. These notifications help warehouse staff take immediate corrective action before problems escalate.

h. Data Integration

Modern warehouse management systems are often integrated with other business systems such as Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) systems. This allows the dashboard to pull relevant data from multiple sources and provide a holistic view of operations.

Videos of Warehouse Admin

3. Importance of a Warehouse Management Dashboard

Warehouse management is the backbone of supply chain operations, and inefficiencies in the warehouse can have a ripple effect on the entire business. A WMS Dashboard plays an essential role in improving warehouse efficiency, reducing costs, and enhancing overall operational performance. Some of the key reasons why a Warehouse Manager Dashboard is important include:

a. Real-Time Decision Making

With the ability to monitor warehouse operations in real-time, a Transport Management System Dashboard enables managers to make decisions based on current data, rather than outdated information. Whether it’s adjusting stock levels, reallocating workforce resources, or addressing delays, real-time data helps ensure quick and accurate decision-making.

b. Operational Efficiency

A Warehouse Dashboard provides visibility into all aspects of warehouse operations, from inventory management to shipping. This transparency allows managers to identify inefficiencies, such as underperforming staff or delayed orders, and address them promptly. By optimizing processes, warehouses can operate more efficiently, reducing costs and improving service levels.

c. Improved Inventory Management

Effective inventory management is crucial for minimizing costs and ensuring products are available when needed. The real-time inventory tracking feature of a WMS Dashboard ensures that managers can easily monitor stock levels, identify discrepancies, and prevent stockouts. By maintaining an optimal inventory level, businesses can improve customer satisfaction and avoid excess stock, which ties up valuable resources.

d. Enhanced Accuracy

Warehouse errors, such as incorrect shipments or misplaced inventory, can have significant consequences for a business. A Warehouse Management Dashboard reduces the risk of such errors by providing staff with accurate, up-to-date information. Whether it’s ensuring correct order picking or tracking inventory movements, the dashboard helps improve accuracy across all warehouse operations.

e. Better Workforce Management

Effective workforce management is a key component of warehouse success. A WMS Dashboard helps managers track employee performance, assign tasks, and identify areas for improvement. By monitoring workforce productivity, businesses can better allocate resources, reduce labor costs, and optimize staffing levels according to demand.

f. Increased Customer Satisfaction

The ultimate goal of any warehouse operation is to meet customer expectations. A Warehouse Manager Dashboard supports this goal by ensuring that orders are processed accurately and delivered on time. With tools for tracking order fulfillment and shipping statuses, managers can proactively address potential delays and keep customers informed, leading to higher satisfaction and repeat business.

g. Proactive Issue Resolution

The dashboard provides real-time alerts and notifications for potential problems, such as inventory shortages, delayed shipments, or order fulfillment issues. By addressing these issues promptly, warehouse managers can prevent costly disruptions to operations and minimize the impact on customers.

4. Benefits of Using a Warehouse Management Dashboard

Implementing a Warehouse Management Dashboard offers a range of benefits to businesses, including:

a. Improved Operational Visibility

A WMS Dashboard gives managers a comprehensive view of warehouse activities, helping them monitor operations at all times. This visibility is critical for identifying inefficiencies, reducing bottlenecks, and making data-driven decisions.

b. Cost Savings

By improving efficiency, accuracy, and workforce management, a Inventory Management Dashboard helps reduce operational costs. Businesses can minimize stockouts, avoid excess inventory, optimize labor usage, and reduce the risk of errors, all of which contribute to cost savings.

c. Faster Order Fulfillment

With real-time data and optimized workflows, warehouses can fulfill orders faster. A Warehouse Management Dashboard provides visibility into order statuses, inventory levels, and workforce allocation, allowing warehouses to prioritize tasks and meet delivery deadlines more effectively.

d. Better Resource Allocation

By monitoring workforce performance and tracking inventory movements, managers can allocate resources more effectively. For instance, if a certain product is selling quickly, additional staff can be assigned to picking and packing that product, ensuring orders are fulfilled without delay.

e. Enhanced Reporting and Analytics

A WMS Dashboard provides in-depth reporting and analytics features, enabling managers to track KPIs, evaluate performance, and identify trends. These insights can be used for long-term strategic planning and continuous improvement.

f. Scalability

As businesses grow, so do their warehouse operations. A Warehouse Management Dashboard is scalable, meaning it can adapt to the evolving needs of the business. Whether the warehouse is expanding in size or handling an increased volume of orders, the dashboard can grow alongside the business.

5. Challenges of Implementing a Warehouse Management Dashboard

While the benefits of a Inventory Management Dashboard are clear, implementing such a system can come with challenges. Some of these challenges include:

a. Integration with Existing Systems

Integrating the WMS Dashboard with existing business systems, such as ERP and CRM, can be complex. This requires proper planning, resources, and technical expertise to ensure smooth integration and data flow across systems.

b. Cost of Implementation

The initial investment in a Warehouse Management Dashboard, including software, hardware, and training, can be substantial. However, the long-term benefits, such as cost savings and increased efficiency, often justify the investment.

c. User Training

Warehouse staff must be adequately trained to use the new system effectively. Training programs should be comprehensive and tailored to different user roles to ensure smooth adoption.

Conclusion

A Warehouse Manager Dashboard is a powerful tool that provides warehouse managers with the insights needed to optimize operations, reduce costs, and improve customer satisfaction. By offering real-time data, key performance metrics, and alerts, the dashboard helps businesses streamline their processes, improve accuracy, and enhance decision-making.

While implementing a WMS Dashboard may present challenges, the long-term benefits—such as improved efficiency, better resource allocation, and increased scalability—make it an invaluable asset for any modern warehouse operation. As e-commerce and supply chain demands continue to grow, a well-implemented Workforce Management Dashboard can be a key driver of business success.

Buy Now and Get Started Today!

Click below to purchase and start unlocking the full potential of your business!

skip to Main Content

skip to Main Content

This Post Has 0 Comments